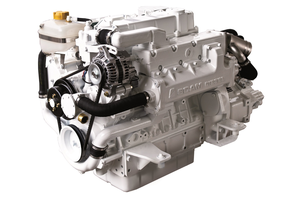

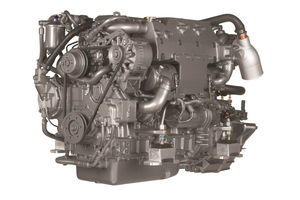

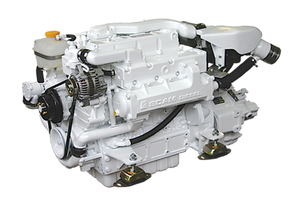

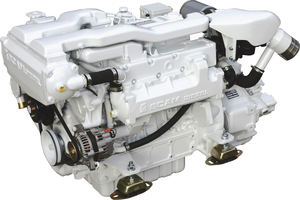

Propulsion

Various engine and propulsionsystems available for the Nano Workboat

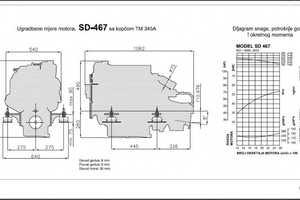

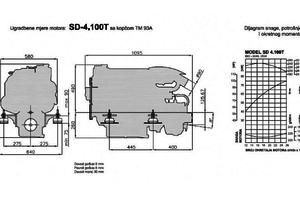

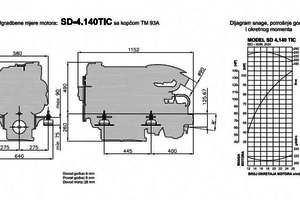

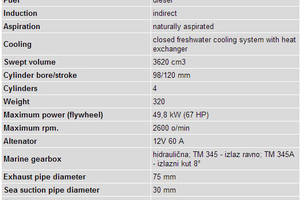

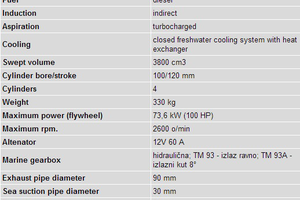

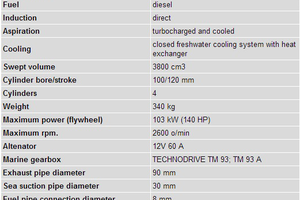

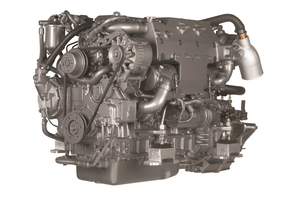

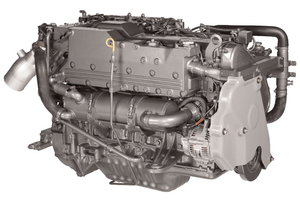

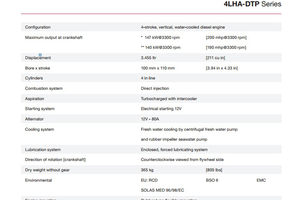

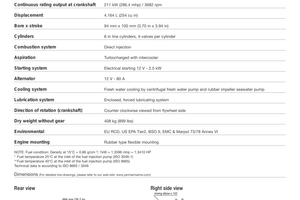

Depending on its operational usage the Nano workboat can be provided with various propulsionsystems and a variety of engine types. The most common engine installation is an inboard diesel engine with shaftline propulsion. But also a sterndrive or even a yetdrive propulsionsystem is possible. The engines normally will be watercooled but also an aircooled Hatz engine can be installed for usage in areas where as waterpolution or waterflora can disturb the waterintake of coolingwater. The Nano Workboat can also be provided with one or two outboard engines.